>Welding Symbols - The Basics <

- Edge welds Slot welds Brazing symbols Nondestructive examination symbols General provisions for welding symbols This course is comprised of modules which will provide complete details on all types of weld and supplementary symbols. It will include a key and graphical representation of each type of weld symbol and supplementary symbols.

- Slot and Plug Weld Symbols Table of Contents show Holes or slots in the arrow side member of a joint for plug or slot welding must be indicated by placing the weld symbol on the side of the reference line toward the reader (A, fig.

Penetration groove welds, the required weld size, as de-fined in this code. Shop or working drawings shall spec-ify the groove depths (S) applicable for the weld size (E) required for the welding process and position of welding to be used. 2.2.4 Groove Welds. Detail drawings shall clearly indi-cate by welding symbols or sketches the details of. The flat contour symbol is now limited to fillet welds, while the flush symbol is used for other welds, such as groove, plug, and slot. Combination groove weld symbol designating two different edge shapes. This is a major change in which one groove weld symbol may be drawn backward (e.g., flare bevel and bevel) to demonstrate actual. Plug or Slot Weld Symbol. Arrow Side; 17 What does this symbol Represent? 5/16 5/16 18 Single-Bevel-Groove and Double Fillet Weld Symbol 5/16 5/16 19 Single-Bevel-Groove and Double Fillet weld Symbols 20 Chain Intermittent Fillet Weld. Weld both sides each end and 10 inches center to center in between; 1/4.

Note: If you're looking for the chart featured in Google Images, scroll down below the welding school ad on the right side.

Like other aspects of drafting, there's a set of symbols for welding to simplify the communication between designer and builder (i.e. the welder). This language may seem a little strange at first, so it's best to learn it one symbol at a time. For example, check out the horizontal stick figures below:

- -

These figures represent the core structure of every drafting specification for a weld to be performed. The welding symbol has an arrow, which points to the location on the drawing where a weld is required. The arrow is attached to a leader line that intersects with a horizontal reference line. Finally, there's a tail at the opposite end of the reference line that forks off in two directions. The tail is optional and needed only for special instructions.

Get the 5-page magazine format version ready-to print now and a copy emailed to your inbox, Your secure purchase helps to maintain this site on a commercial web server. Payments thru TheCityEdition.com editor. (Note: You do not need a Paypal account.)

- - - - - - - - - - - - - - - - - - - - - - - - -

Dangling from the middle of the reference line, you'll see a geometric shape or two parallel lines identifying what type of weld should be performed on the metal. This is called the weld symbol (not to be confused with the overall welding symbol ). The three weld symbols you see in the drawings above represent a square, fillet and V-groove weld, respectively.

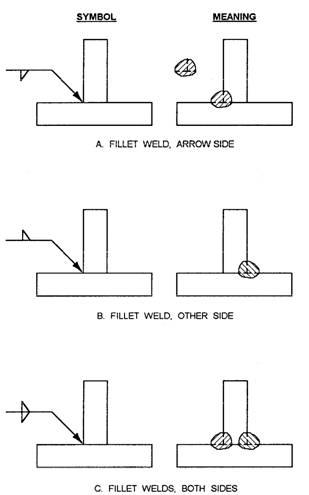

The weld symbol may also be placed above the reference line, rather than below it. This placement is important. When the weld symbol hangs below the reference line, it indicates that the weld must be performed on the 'arrow side' of the joint. For example, In the next drawing a fillet weld is specified on the arrow side. You can see the actual weld in the second depiction.

Now, if the weld symbol appears on top of the reference line, then the weld should be made on the opposite side of the joint where the arrow points. Here's how that will look:

If the weld symbol appears on both sides of the reference line, as shown below, it specifies that a weld must be performed on both sides of the joint.

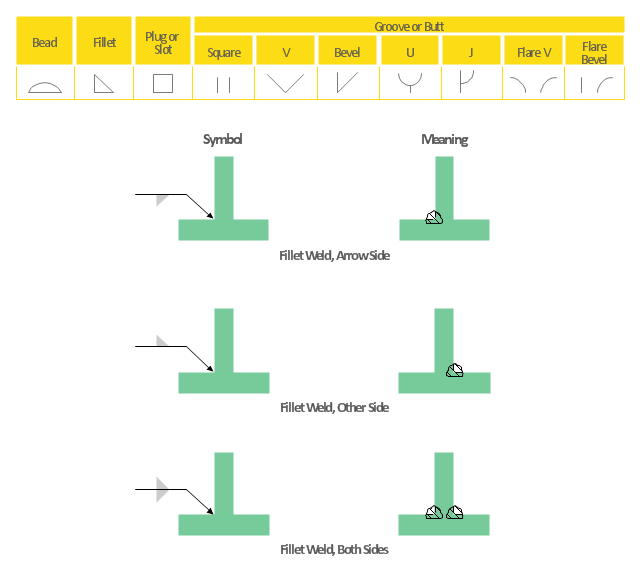

Numerous weld symbols have been devised to represent all the different weld types used in the trade, as well as any joints that must be cut or beveled during fit-up. Here are the most common ones to learn:

If you're not familiar with either welds or joints, be sure to check out those topics in the green menu box located on the top right side of this page. Even if you are familiar, it still takes time to memorize all these symbols and what type of welds they represent. Therefore, it's a good idea to print out or photocopy a chart that contains both the symbols and drawings of the completed welds. Click here to download a sample chart or look below right of this column.

Dimensions and Angles

Needless to say, numbers are also a big part of a welding specification. The width, depth, root opening and length of a weld, as as well as the angle of any beveling required on the base metal before welding can all be communicated succintly above or below the reference line.

In most cases, the weld width (or diameter) is located to the left of the weld symbol (expressed here in inches), while its length is written to the right . (As explained in Anatomy of a Weld, the weld's width is the distance from one leg of the weld to the other.) Often, no length is indicated, which means the weld should be laid down from the beginning to the end of the joint, or where there's an abrupt change in the joint on the base metal.

Dimensions written below the reference line, of course, apply to the joint on the arrow side, while dimensions written above apply to the joint on the other side. In the image above, welds are indicated for both sides of the joint.

Sometimes, a series of separate welds is specified, rather than a single long weld. This is common when thin or heat-sensitive metals are welded on, or where the joint is a really long one. In the following symbol and drawing, 3-inch intermittent fillet welds are specified:

--

Notice that the weld symbols on either side of the reference line above are offset, rather than mirroring each other. This means the welds should be located at staggered spots on either side of the joint, as shown in the drawing on the right.

A weld symbol may also specify an angle, root opening or root face dimension. This is common when the base metal to be welded on is thicker than 1/4 inch. The following example is a symbol and drawing calling for a V-groove joint:

- -- - - - --

Here, the groove weld has dimensions written inside the symbol. The first is 1/8 , which pertains to a root opening of 1/8 inch. The larger number below it signifies 45 degrees, which represents the included angle between the plates. 'Included' means the sum of the angles beveled on each side. So in this example the bevel made on each plate is 22 1/2, which equals 45 degrees.

Other Symbols and Multiple Reference Lines

Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below:

- - - - - - -- -

A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop. The weld-all-around circle, located at the same juncture, means just that. While this symbol is often used in pipe and tubing, a non-circular structural component (as shown above right) may likewise need welding on all sides.

Here are a few other types of instructions you might see on a drawing:

- - - - - -

A curve located above the weld symbol's face specifies that the finished weld should be either flat, convex or concave. (If you see a straight line, then it's a flat weld - i.e. flush face.) As shown on the top right, a V-groove weld symbol with a box above it indicates a backing strip or bar is required for this joint. The strip or bar must be welded onto the back side of the joint before the groove weld is performed.

A backing strip or bar is sometimes confused with a 'back weld ' or a 'backing weld'. They are not the same thing as using a backing strip. A back weld is where a second weld is created on the back side of the joint after the primary groove weld is completed. Conversely, a backing weld is a weld that the welder performs first (so it serves the same function as a backing strip). A backing strip is a piece of metal welded on to the bottom of the plates to facilitate a smooth, even weld. Each of these three options are illustrated below using both the tail and the weld symbol to communicate what needs to happen.

As you can see, the only difference between the back and backing welds is when they're performed. The symbols look the same, so both must be specified by name. In the third symbol, the dimensions and type of steel (A-38) for the backing strip are specified.

When a welding operation involves a lot of steps, you will sometimes see multiple reference lines on the welding symbol, as shown below:

To keep the instructions clear, several reference lines may extend from the leader line at a parallel trajectory. Each line represents a separate operation and is performed in order, beginning with the line closest to the arrow.

Optional Tail = Special Instructions

As you just saw in the case of the backing strip, the forked tail of the welding symbol is used to convey details that aren't part of the normal parameters declared on the reference line. For instance, the engineer or designer might want the welder to use stick welding (i.e. SMAW), or another welding process. Or there may be other information to convey:

Of course, when no special instructions are needed, the tail is omitted from the welding symbol, leaving just the reference line, arrow and leader line.

More Complicated Welding Specifications

Once you master the basics, you'll be ready to absorb the many other particulars conveyed on shop drawings and blueprints. Among the most common:

- • Finish and contour instructions

- • Countersink and chamfer specs

- • Grinding or other machining

- • Spot or plug weld instructions

Below you'll find the standard chart that's used to communicate information with a welding symbol. You may need to refer to it when there are lots of dimensions listed or uncommon specifications to sort out.

To research welding symbols further, follow the links in the resource box on the upper right of this page. The Lincoln Foundation also publishes a book, 'How to Read Shop Drawings', which costs $10 if you purchase it from their website. (See the link above right.)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Next: Weld Defects

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

If you have any website suggestions or concerns, email rregello [at] thecityedition [dot] com.

Return to Main Menu

Copyright © 2012-2021 TheCityEdition.com

Aws Slot Weld Symbol

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Also be sure to checkout:

Budget Guide to Europe (slide show)

Judy talked to you on Wednesday about five of the most common mistakes made when reading welding symbols. You'd think that would cover it all, right? Wrong. I'm here to tell you that we have more, five more in fact. (I bear great news, don't I?) As Judy mentioned, trying to decipher AWS 2.4 initially came to us as a feat comparable to decoding ancient Egyptian hieroglyphs. From the outside looking in, these symbols were merely circles, triangles, and rectangles idly sitting on a line that pointed to what seemed to be the letter 'T'. Puzzling indeed. Slowly, and I mean slowly, these geometric shapes and th at letter 'T' came to mean more, and now that we have made welding symbols more accessible, we know it will be clearer to others as well.

You've seen Judy's starting lineup of mistakes; now let's take a look at the next string.

Mistake No. 6: Weld Symbol vs. Welding Symbol

While these two words sound the same, they imply very different things. A welding symbol is the entire image as it appears on a plan. It includes information such as a reference line, an arrow, weld dimensions, notes, as well as the weld symbol. A weld symbol is a single element that is part of a welding symbol. It indicates what type of weld is to be applied to the joint. Think about it this way, a welding symbol is made up of weld symbols, but a weld symbol is not made up of welding symbols.

Mistake No. 7: Weld Process References

To indicate that a specific weld process is to be used, an abbreviation is placed within the tail of a welding symbol. For example, the abbreviation for electron beam welding is EBW and the abbreviation for gas tungsten arc welding is GTAW. So, naturally, the abbreviation for resistance spot weld is RSW, right? If this is so, then what is the abbreviation for resistance seam weld? These assumptions can land you in hot water, so if there is any confusion, always consult a list of abbreviations.

Mistake No. 8: Views of a Joint

This first image shown here is the top view of a corner joint. The second image shows the side view of a T-Joint. Notice any resemblance? That's because these two images are exactly the same. If there is ever any doubt, look for another view of the joint on the plans or ask a supervisor in order to be absolutely certain before welding.

Plug Vs Slot Weld Symbols

Penetration groove welds, the required weld size, as de-fined in this code. Shop or working drawings shall spec-ify the groove depths (S) applicable for the weld size (E) required for the welding process and position of welding to be used. 2.2.4 Groove Welds. Detail drawings shall clearly indi-cate by welding symbols or sketches the details of. The flat contour symbol is now limited to fillet welds, while the flush symbol is used for other welds, such as groove, plug, and slot. Combination groove weld symbol designating two different edge shapes. This is a major change in which one groove weld symbol may be drawn backward (e.g., flare bevel and bevel) to demonstrate actual. Plug or Slot Weld Symbol. Arrow Side; 17 What does this symbol Represent? 5/16 5/16 18 Single-Bevel-Groove and Double Fillet Weld Symbol 5/16 5/16 19 Single-Bevel-Groove and Double Fillet weld Symbols 20 Chain Intermittent Fillet Weld. Weld both sides each end and 10 inches center to center in between; 1/4.

Note: If you're looking for the chart featured in Google Images, scroll down below the welding school ad on the right side.

Like other aspects of drafting, there's a set of symbols for welding to simplify the communication between designer and builder (i.e. the welder). This language may seem a little strange at first, so it's best to learn it one symbol at a time. For example, check out the horizontal stick figures below:

- -

These figures represent the core structure of every drafting specification for a weld to be performed. The welding symbol has an arrow, which points to the location on the drawing where a weld is required. The arrow is attached to a leader line that intersects with a horizontal reference line. Finally, there's a tail at the opposite end of the reference line that forks off in two directions. The tail is optional and needed only for special instructions.

Get the 5-page magazine format version ready-to print now and a copy emailed to your inbox, Your secure purchase helps to maintain this site on a commercial web server. Payments thru TheCityEdition.com editor. (Note: You do not need a Paypal account.)

- - - - - - - - - - - - - - - - - - - - - - - - -

Dangling from the middle of the reference line, you'll see a geometric shape or two parallel lines identifying what type of weld should be performed on the metal. This is called the weld symbol (not to be confused with the overall welding symbol ). The three weld symbols you see in the drawings above represent a square, fillet and V-groove weld, respectively.

The weld symbol may also be placed above the reference line, rather than below it. This placement is important. When the weld symbol hangs below the reference line, it indicates that the weld must be performed on the 'arrow side' of the joint. For example, In the next drawing a fillet weld is specified on the arrow side. You can see the actual weld in the second depiction.

Now, if the weld symbol appears on top of the reference line, then the weld should be made on the opposite side of the joint where the arrow points. Here's how that will look:

If the weld symbol appears on both sides of the reference line, as shown below, it specifies that a weld must be performed on both sides of the joint.

Numerous weld symbols have been devised to represent all the different weld types used in the trade, as well as any joints that must be cut or beveled during fit-up. Here are the most common ones to learn:

If you're not familiar with either welds or joints, be sure to check out those topics in the green menu box located on the top right side of this page. Even if you are familiar, it still takes time to memorize all these symbols and what type of welds they represent. Therefore, it's a good idea to print out or photocopy a chart that contains both the symbols and drawings of the completed welds. Click here to download a sample chart or look below right of this column.

Dimensions and Angles

Needless to say, numbers are also a big part of a welding specification. The width, depth, root opening and length of a weld, as as well as the angle of any beveling required on the base metal before welding can all be communicated succintly above or below the reference line.

In most cases, the weld width (or diameter) is located to the left of the weld symbol (expressed here in inches), while its length is written to the right . (As explained in Anatomy of a Weld, the weld's width is the distance from one leg of the weld to the other.) Often, no length is indicated, which means the weld should be laid down from the beginning to the end of the joint, or where there's an abrupt change in the joint on the base metal.

Dimensions written below the reference line, of course, apply to the joint on the arrow side, while dimensions written above apply to the joint on the other side. In the image above, welds are indicated for both sides of the joint.

Sometimes, a series of separate welds is specified, rather than a single long weld. This is common when thin or heat-sensitive metals are welded on, or where the joint is a really long one. In the following symbol and drawing, 3-inch intermittent fillet welds are specified:

--

Notice that the weld symbols on either side of the reference line above are offset, rather than mirroring each other. This means the welds should be located at staggered spots on either side of the joint, as shown in the drawing on the right.

A weld symbol may also specify an angle, root opening or root face dimension. This is common when the base metal to be welded on is thicker than 1/4 inch. The following example is a symbol and drawing calling for a V-groove joint:

- -- - - - --

Here, the groove weld has dimensions written inside the symbol. The first is 1/8 , which pertains to a root opening of 1/8 inch. The larger number below it signifies 45 degrees, which represents the included angle between the plates. 'Included' means the sum of the angles beveled on each side. So in this example the bevel made on each plate is 22 1/2, which equals 45 degrees.

Other Symbols and Multiple Reference Lines

Moving to another part of the overall welding symbol, at the intersection of the reference line and the leader line, two other symbols may be inserted, as shown below:

- - - - - - -- -

A flagpole indicates a field weld, which simply tells the welder to perform the work on site, rather than in the shop. The weld-all-around circle, located at the same juncture, means just that. While this symbol is often used in pipe and tubing, a non-circular structural component (as shown above right) may likewise need welding on all sides.

Here are a few other types of instructions you might see on a drawing:

- - - - - -

A curve located above the weld symbol's face specifies that the finished weld should be either flat, convex or concave. (If you see a straight line, then it's a flat weld - i.e. flush face.) As shown on the top right, a V-groove weld symbol with a box above it indicates a backing strip or bar is required for this joint. The strip or bar must be welded onto the back side of the joint before the groove weld is performed.

A backing strip or bar is sometimes confused with a 'back weld ' or a 'backing weld'. They are not the same thing as using a backing strip. A back weld is where a second weld is created on the back side of the joint after the primary groove weld is completed. Conversely, a backing weld is a weld that the welder performs first (so it serves the same function as a backing strip). A backing strip is a piece of metal welded on to the bottom of the plates to facilitate a smooth, even weld. Each of these three options are illustrated below using both the tail and the weld symbol to communicate what needs to happen.

As you can see, the only difference between the back and backing welds is when they're performed. The symbols look the same, so both must be specified by name. In the third symbol, the dimensions and type of steel (A-38) for the backing strip are specified.

When a welding operation involves a lot of steps, you will sometimes see multiple reference lines on the welding symbol, as shown below:

To keep the instructions clear, several reference lines may extend from the leader line at a parallel trajectory. Each line represents a separate operation and is performed in order, beginning with the line closest to the arrow.

Optional Tail = Special Instructions

As you just saw in the case of the backing strip, the forked tail of the welding symbol is used to convey details that aren't part of the normal parameters declared on the reference line. For instance, the engineer or designer might want the welder to use stick welding (i.e. SMAW), or another welding process. Or there may be other information to convey:

Of course, when no special instructions are needed, the tail is omitted from the welding symbol, leaving just the reference line, arrow and leader line.

More Complicated Welding Specifications

Once you master the basics, you'll be ready to absorb the many other particulars conveyed on shop drawings and blueprints. Among the most common:

- • Finish and contour instructions

- • Countersink and chamfer specs

- • Grinding or other machining

- • Spot or plug weld instructions

Below you'll find the standard chart that's used to communicate information with a welding symbol. You may need to refer to it when there are lots of dimensions listed or uncommon specifications to sort out.

To research welding symbols further, follow the links in the resource box on the upper right of this page. The Lincoln Foundation also publishes a book, 'How to Read Shop Drawings', which costs $10 if you purchase it from their website. (See the link above right.)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Next: Weld Defects

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

If you have any website suggestions or concerns, email rregello [at] thecityedition [dot] com.

Return to Main Menu

Copyright © 2012-2021 TheCityEdition.com

Aws Slot Weld Symbol

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Also be sure to checkout:

Budget Guide to Europe (slide show)

Judy talked to you on Wednesday about five of the most common mistakes made when reading welding symbols. You'd think that would cover it all, right? Wrong. I'm here to tell you that we have more, five more in fact. (I bear great news, don't I?) As Judy mentioned, trying to decipher AWS 2.4 initially came to us as a feat comparable to decoding ancient Egyptian hieroglyphs. From the outside looking in, these symbols were merely circles, triangles, and rectangles idly sitting on a line that pointed to what seemed to be the letter 'T'. Puzzling indeed. Slowly, and I mean slowly, these geometric shapes and th at letter 'T' came to mean more, and now that we have made welding symbols more accessible, we know it will be clearer to others as well.

You've seen Judy's starting lineup of mistakes; now let's take a look at the next string.

Mistake No. 6: Weld Symbol vs. Welding Symbol

While these two words sound the same, they imply very different things. A welding symbol is the entire image as it appears on a plan. It includes information such as a reference line, an arrow, weld dimensions, notes, as well as the weld symbol. A weld symbol is a single element that is part of a welding symbol. It indicates what type of weld is to be applied to the joint. Think about it this way, a welding symbol is made up of weld symbols, but a weld symbol is not made up of welding symbols.

Mistake No. 7: Weld Process References

To indicate that a specific weld process is to be used, an abbreviation is placed within the tail of a welding symbol. For example, the abbreviation for electron beam welding is EBW and the abbreviation for gas tungsten arc welding is GTAW. So, naturally, the abbreviation for resistance spot weld is RSW, right? If this is so, then what is the abbreviation for resistance seam weld? These assumptions can land you in hot water, so if there is any confusion, always consult a list of abbreviations.

Mistake No. 8: Views of a Joint

This first image shown here is the top view of a corner joint. The second image shows the side view of a T-Joint. Notice any resemblance? That's because these two images are exactly the same. If there is ever any doubt, look for another view of the joint on the plans or ask a supervisor in order to be absolutely certain before welding.

Plug Vs Slot Weld Symbols

Mistake No. 9: Fillet Welds with Unequal Legs

These are tricky. A fillet weld with unequal legs has two separate leg sizes. This can be communicated on a welding symbol using two different methods. The first is by using dimension lines. The area that is encompassed by the dimension lines, receives the dimension indicated next to it, not the member that the dimension line touches. This can also be indicated by using a note written within the tail. Both of these indications also tell us, not only which dimension applies to a specific member, but which dimension applies to the other as well. On a plan, only one dimension needs to be indicated in the drawing in order to assign a leg size to a particular member. As long as you know where one dimension goes, the other dimension applies to the remaining leg by default.

Mistake No. 10: Weld Symbol Doppelgänger

There are a few weld types that use the same weld symbol, such as plug and slot welds and spot and projection welds. When reading these symbols, there are a few ways to differentiate between the two. Let's look at plug and slot welds. With plug welds, the diameter symbol is used to indicate plug weld size since plug welds are round. Slot welds, however, are elongated. They are dimensioned by width and length, a dimension which plug welds do not have. If there is a diameter symbol, then it's a plug weld. If there is no diameter symbol, then it's a slot weld. It's as simple as that.

To get better acquainted with these rules or for more information, check out our latest course: Understanding Welding Symbols, scheduled for publication on March 28th. Within this course, we cover all the mistakes discussed in this blog in addition to the rules that apply to all of the other welding symbols. The course starts with very basic concepts including the five joint types and how they look on a plan, and then it walks you through the more in depth concepts such as, what to do when a fillet weld has uneven legs or how to communicate which weld process is to be used on a joint. From the outside, AWS 2.4 seems like a rather unassuming book of standards, but let me tell you, that little book packs in pounds and pounds of encrypted information within a very thin spine; information needed in order to make the big leap forward to becoming a CWI. With Understanding Welding Symbols, we help to lighten that load so that you can strut a little more confidently toward your goals.

Slot Weld Symbol

Alicia Garcia